Project Description

NEW SOLUTION FOR THE CREATION OF VOID SPACES AND RAINWATER TANK STORAGE SYSTEMS, OF A HEIGHT OF 51 TO 300 CM.

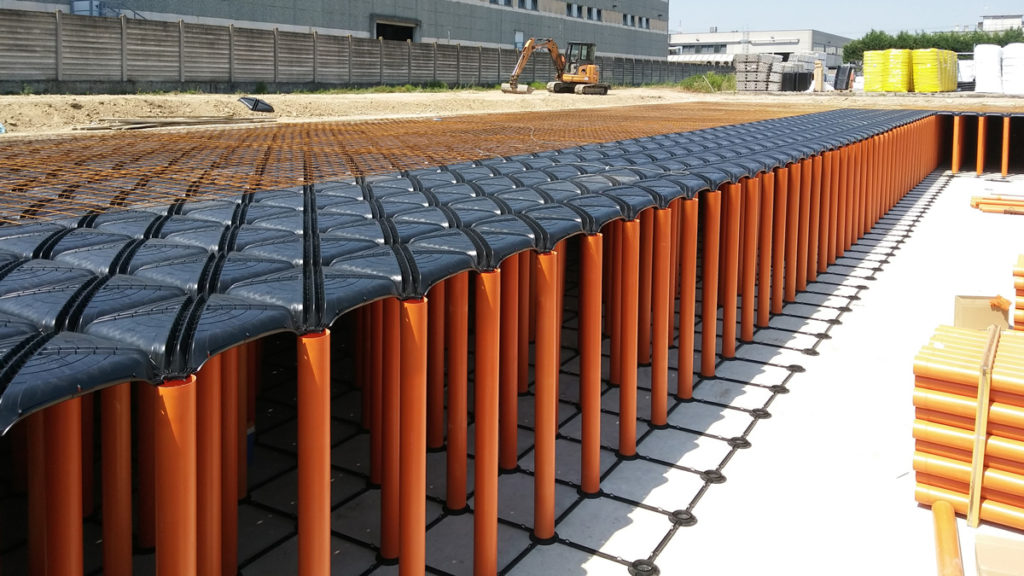

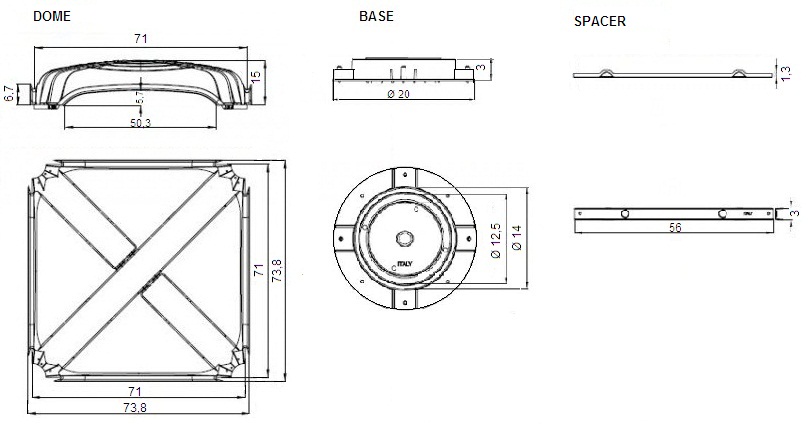

For both solutions, the Evolution System involves the use of a dome made of recycled polypropylene, placed on PVC pipes. The PVC pipes are supported on a base equipped with spacers which ensure the correct positioning on the ground. Evolution System offers the possibility to use pipes of two different diameters, to achieve the most suitable outcome for the type of construction required. The PVC pipe diameter of 12.5 cm (minimum wall thickness 2 mm) up to height 200 cm; or a diameter 14 cm (minimum wall thickness 2 mm) up to height 260 cm; or a diameter 14 cm (minimum wall thickness 3 mm) up to height 300 cm. Each dome mould has a dimension of the internal overlap of 71 x 71 x 15 cm.

RANGE OF USES

Riassumendo con l’utilizzo del Vespaio Aerato Evolution è così possibile realizzare:

- Ventilated foundation of different height variations;

- Rainwater tanks for storage and reuse of rainwater in multiple areas:

- In the private and commercial sector for irrigation or other uses that do not necessarily include drinking water (toilet drain, house cleaning, car washing, flushing, cleaning of premises etc.);

- In the industrial sector for the production processes of washing, cooling, rinsing and any other non-food processing and for fire-fighting systems;

- Stormwater (or rainwater) dispersion tanks to mitigate the effect of flood caused by exceptional weather events. The dispersion tanks are not totally impermeable and allow the gradual release of rainwater into the soil profile through slits on the walls or the draining holes;

- Reinforced concrete tanks to create inclined and multilevel surfaces.

The Evolution System is modular, light, easy to lay and ecological, as it is made of recycled and recyclable plastic material. Nailing the bases to the subfloor, the PVC pipes can be laid quickly and the spacers can be recovered and reused.

With the Evolution System it is possible to support exceptional loads and reach limit heights up to 3 meters, creating rises, unevenness and height balancing. The spacing between the pipes of 71 x 71 cm, combined with the prior installation of entry points, makes it possible inspect the “tank” made with the Evolution System, in order to clean, check the water level and the microbiological status, check piping and installed systems.

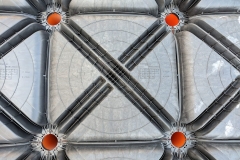

With the Evolution System you end up with a reinforced concrete structure consisting of a foundation slab, perimeter walls and a steel reinforced slab supported by pillars, which are concrete and steel rod fill PVC pipes. The “tank” is suitable to support differential loads from creating a green area or a flooring structure for the transit of heavy vehicles. Local engineering designs should be completed prior to construction to meet local code requirements. The “tank” should be waterproofed and it is necessary to provide a discharge point for the “overflow”.

PRECAUTIONS FOR USE

The Evolution System must be installed with the operator on the ground, if the height to be achieved does not allow it , then the use of ladder or adequate safety devices is required.

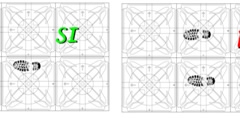

After installing the Evolution System it is possible to walk on. For heights of more than one meter, evaluate the need to use wooden planks or other appropriate safety devices.

Do not place any loads on the Evolution System such as construction site material like pallets, cement bags, etc. before completion.

IMPORTANT: On casting the concrete, the beams and sides are to the cast first before the floor is completed to the finished height.

- Prepare the laying ground and make the concrete foundation, the thickness depends on the support loads required. Local engineering designs should be completed prior to construction to meet local code requirements;

- Lay the Evolution System (base, spacer, PVC pipe and dome) as shown in the installation below on well leveled base:

- Cut the pipes at right angles and to the required length;

- Anchor the perimeter pipes, to the wall with fixed with pipe collar. If the assembly ends with a whole dome proceed by anchoring the perimeter pipes to the wall with the fixed pipe collar; the fixing points of the pipes to the wall must be accommodated according to the height of the pipe used;

- The domes can be cut to size using a disc grinder/cutter;

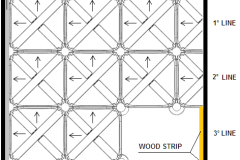

- Lay wood strips 8 cm wide and 2 cm thick, fixed to the wall, to place the Evolution System domes cut to size;

- Prepare the polystyrene strips along the semi-perimeter where the assembly started to prevent the passage of the concrete. The first strip must be cut to 81 cm;

- Lay the steel mesh of the dimension indicated in the structural calculations, possibly adding some steel rods inside the PVC pipes to reinforce the concrete pillars. Connect the rods inserted inside the tubes with the steel mesh;

- Cast the concrete by positioning over the dome and gradually distributing the concrete over the entire surface; do not direct the concrete casting directly into the pipes. On the first pass the pipe are only to be filled to 1/3 and then you should give it a little time for the concrete to harden, then complete the filling the pipe on the second pass and the dome until it reaches the project height.

Lay the Evolution System from left to right and from top to bottom, always keeping the arrows printed on the dome at the top and on the left.

1 m² of EVOLUTION SYSTEM

- N° 2 dome of dimension of the internal overlap 71 x 71 x 15 cm

- N°2 PVC pipes Ø 12,5 o 14 cm

- N° 2 bases

- N° 4 spacers

The exact amount of bases, pipes and spacers can vary depending on the surface configuration.

CONSUPTIONS

Concrete consumption of satin dome m3/m2 0,033

Concrete consumption per m2 per meter of pipe height Ø 12,5 cm m3/m2 *m 0,023; Ø 14 cm m3/m2 *m 0,029

Example of calculation of the concrete consumption:

- Surface required m² 1

- Height required cm 100

- Dome height cm 15

- Pipe height cm 85

- Concrete consumption of satin dome m³/m² 0,033

- Concrete consumption to fill the pipe: ∅ 12,5 cm m³/m² * m 0,023 * m 0,85 = m³/m² 0,019

- Total concrete consumption of satin dome = m³/m² 0,052

ASK FOR A FREE QUOTATION

The Evolution System completes the production line Foundation Moulds.

The images and features shown in this publication are not binding.

Plastics 3F srl reserves the right to make changes to the products without any prior notice.

Follow us on our Facebook page.